Maintenance & Videos

Use only approved restraining procedures such as the guidelines in our handcuff manual. Frequent review and practice of proper procedures will increase your safety and efficiency. Approved procedures will also help to ensure your restraints continue to function properly.

While Peerless® restraints are designed and manufactured to take abuse avoid dropping onto or banging against hard surfaces.

Restraints should receive regular care and maintenance. Inspect them frequently. Keep the ratchet and key hole free of dirt, lint or other foreign substances which may hinder proper functioning. The following is a video showing how to perform an in-field function check to evaluate if your restraint is working properly:

<iframe src="https://www.youtube.com/embed/YslRh--XDw8?rel=0" width="560" height="315" frameborder="0" allowfullscreen=""></iframe>

When unlocking your restraint be careful not to torque the key guide post. This will loosen the post causing it to fall out. Also, be careful not to over rotate the key causing the key flag to break off or become stuck in the locking mechanism. Use extra caution when using oversize keys.

The following is a video showing how to lock and unlock Peerless standard restraints:

<iframe src="https://www.youtube.com/embed/ccUJf3N87yk?rel=0" width="560" height="315" frameborder="0" allowfullscreen=""></iframe>

When possible carry your restraints in a protective case to reduce exposure to outside elements. If exposed to moisture dry thoroughly. Most importantly, dry the inside locking mechanisms. Use a hair dryer if necessary to force moisture out of the lock cavity. Avoid temperatures above 300° Fahrenheit. After drying re-lubricate following the instructions:

Standard Products and Color Plated Restraints Maintenance

Standard product and color plated product should be lubricated as needed. The frequency will depend on how the cuffs are stored, how often they are used and the environment they are used in.

It is best to use a high quality light weight lubricant. Heavy or greasy oils will clog the lock mechanism and attract dirt or other debris. Penetrate (black oxide) finishes may require more frequent lubrication and may tend to rust if not kept properly oiled.

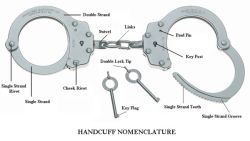

Drip or spray the oil in small amounts to the areas shown below. Use as little oil as necessary.

Work the oil into these important areas by ratcheting the single strand, locking, double locking and unlocking the cuff. After lubrication remove all excess oil from handling surfaces so the restraints are not slippery.

The following lubricants are recommended:

085 Ultra Bore or Special Forces Dry Lube: Both are made by Otis Technologies. They are high quality , light weight and non-greasy lubricants. They can be found in most law enforcement supply stores or gun supply stores.

Tri-Flow: Made by Tri-flow Lubricants. Teflon based - light weight and non-greasy. More information at triflowlubricants.com. Found at most hardware stores.

WD40: A good inexpensive lubricant. Found at most hardware stores.

The following is a video showing how to perform basic care and maintenance for Peerless restraints:

<iframe src="https://www.youtube.com/embed/ilBhUZvqsXM?rel=0" width="560" height="315" frameborder="0" allowfullscreen=""></iframe>

If the restraints are contaminated by blood, vomit or other substances, use appropriate disinfecting techniques. See FAQ's for more information.

High Security Restraint Maintenance

Use the following instructions for lubricating and disinfecting Peerless High Security restraints. Do not use maintenance guidelines for standard and color plated products.

Important: Care should be taken when using cleaning solvents and lubricants on high security restraints. Different chemicals, temperatures and stress can have adverse effects on the LEXAN® thermoplastic lock housing.

Cleaning: The Lexan® portion of the Handcuffs or Leg Irons may cleaned with a mild soap and water only! Complete immersion is not recommended and should be avoided. Care should be taken to remove all remaining cleaning agents with forced-air drying or warm water. Hot water above 140ºF should be not be used.

Lubrication: Routinely clean and lightly oil the ratchet area and double strand rivet area to insure proper operation. Avoid getting any lubricants on the LEXAN® thermoplastic lock housing parts. Do not use any lubricant other than a Silicone Mold Release lubricant; such as SLIDE product #: 40112N

Cleaning & Disinfecting

First it is important to note we are not specialists in disinfecting techniques. Any information provided by us should be double checked with experts in this area. For more information call the Center for Disease Control (CDC) at 800-342-2437.

Disinfecting Techniques - Standard Product

There are a few different ways agencies/departments clean and disinfect restraints.

The first is to use commercial products. The following are disinfecting agents for use on hard non-porous surfaces. In general they are effective against various Herpes, Influenza, HIV-1 (AIDS virus), tuberculosis and other organisms. They are easy to use and will not damage a nickel plated finish. These cleaners will effect Black Oxide or Penetrate finishes.

- Medaphene Spray – available through Romaine Companies (800) 850-6985.

- Redicide – available through Chemclean Corporation (800) 538-2436.

- Staphene Spray – available through Calgon Vestal Laboratories (800) 345-7995.

Ultrasonic cleaning is another option. Many large agencies or departments have ultrasonic cleaning tanks for firearms maintenance. The same process can be used for cleaning and disinfecting our standard product. Do not use ultrasonic cleaning methods with Peerless high security restraints and color plated restraints.

For ultrasonic cleaning systems, we use and recommend, products from L&R Manufacturing Company. L&R offers a wide range of ultrasonic cleaning solutions at:

L&R Manufacturing Company

577 Elm Street

Kearny, NJ 07032

Phone: (201) 991-5330

Fax: (201) 991-5870

Website: lrultrasonics.com

L&R's UltraDose Germicidal Hospital Grade Ultrasonic Cleaner Concentrate is claimed to be COVID-19 effective. More info at: lrultrasonics.com/solutions/ultradose-germicidal-ud036.

Another option is to use a bleach bath. Mix 1 part bleach to 10 parts water. Soak the cuffs for 10 min. and then following the instructions below. The bleach may cause the nickel finish to cloud or tarnish. Do not use this method for product with black oxide finish, color plated finish or our high security restraints.

Do not place cuffs in boiling water. This may effectively disinfectant the restraint but can cause heavy rusting.

After using appropriate disinfecting techniques it is very important to thoroughly clean and dry the restraint. The single strand pivot area and the internal lock parts are most important. Use a hair dryer if necessary to force moisture out of the lock cavity. Avoid temperatures above 300° Fahrenheit. If the internal parts are not thoroughly dry, rusting and corrosion will become a problem leading to improper or poorly functioning restraints.

All Peerless Handcuff Company restraints use stainless steel or nickel plated internal lock parts. This will help stop rusting or corrosion issues. It will not prevent it.

Black Oxide finishes may require more frequent lubrication and may tend to rust if not kept properly oiled.

Disinfecting Techniques - Color Plated Products and High Security Restraints:

Use the following to disinfect Peerless color plated product and high security restraints.

Important - High Security Restraints: Care should be taken when using cleaning solvents and lubricants on high security restraints. Different chemicals, temperatures and stress can have adverse effects on the LEXAN® thermoplastic lock housing.

Cleaning Color Plated and High Security Restraints: Clean with mild soap and warm water only! Hot water above 140ºF should be not be used. Care should be taken to remove all remaining cleaning agents with forced-air drying or warm water. For high security restraints complete immersion is not recommended and should be avoided.

After disinfecting the restraint should be lubricated. See maintenance for more proper lubrication information.

Please remember to double check all advice given with experts in disinfectants techniques.